Project

Integration of high-end CNC kernel

Integration of the ISG CNC kernel in CODESYS Control and corresponding configuration editor

Request/problem:

Our customer develops and markets motion control systems based on IPC architectures. For very demanding motion, CNC and robotics applications, he has decided to use the technology from ISG. The CNC kernel needs to be integrated into the CODESYS Control runtime system and the automation engineer should be able to configure the system directly in CODESYS via new plug-in editors.

Solution:

This demanding task requires much knowledge both on the CODESYS Control runtime side and CODESYS Automation Platform.

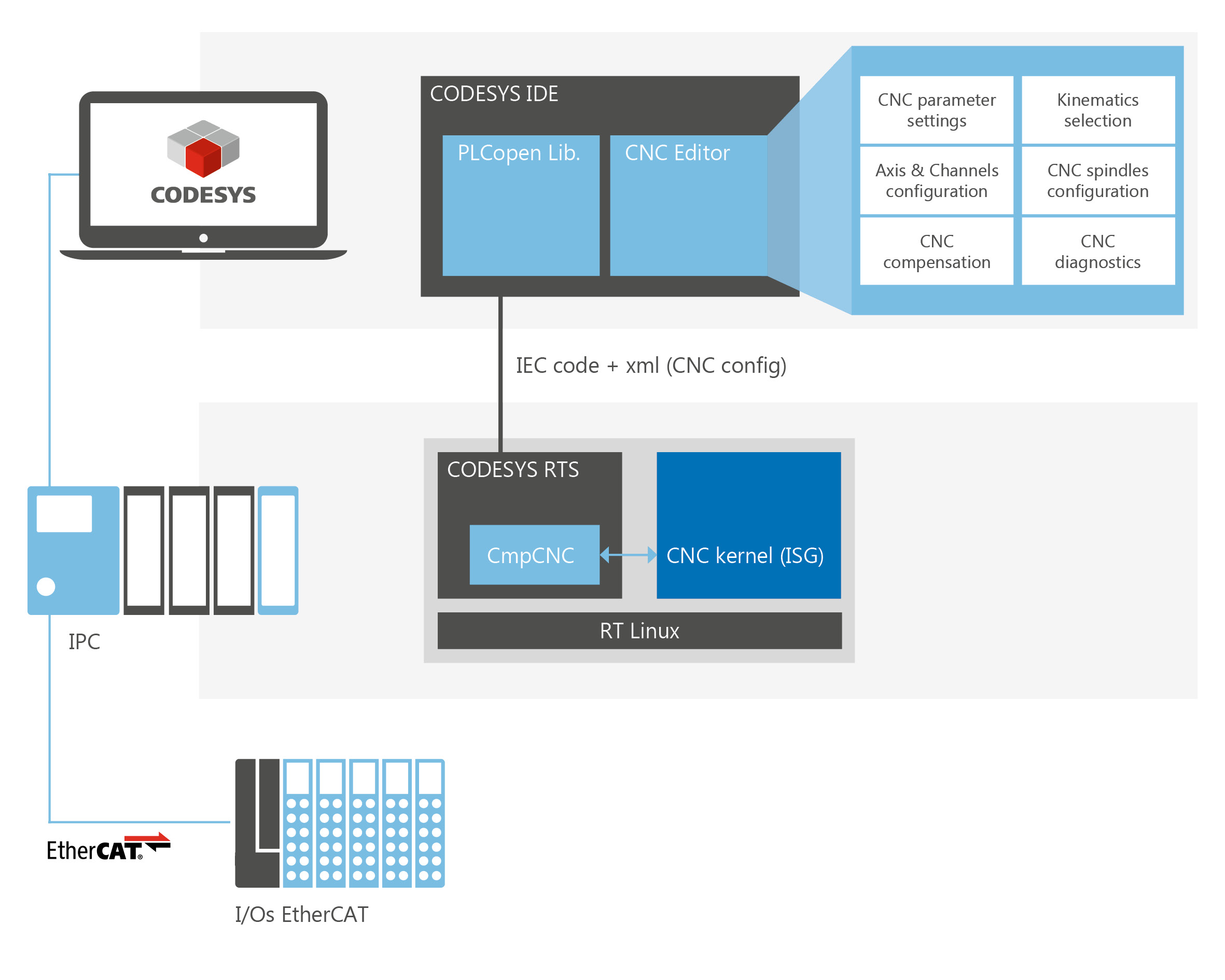

The CNC-Kernel was built in the runtime system in the form of a CODESYS component. Such a component handles CNC-configuration in XML, which is generated by the CODESYS Plug-In. This configuration is transferred to the CNC-Kernel, which performs initialization and starts controlling the configured drives via EtherCAT. The component performs synchronization between IEC-Tasks in CODESYS and tasks in the ISG-Kernel.

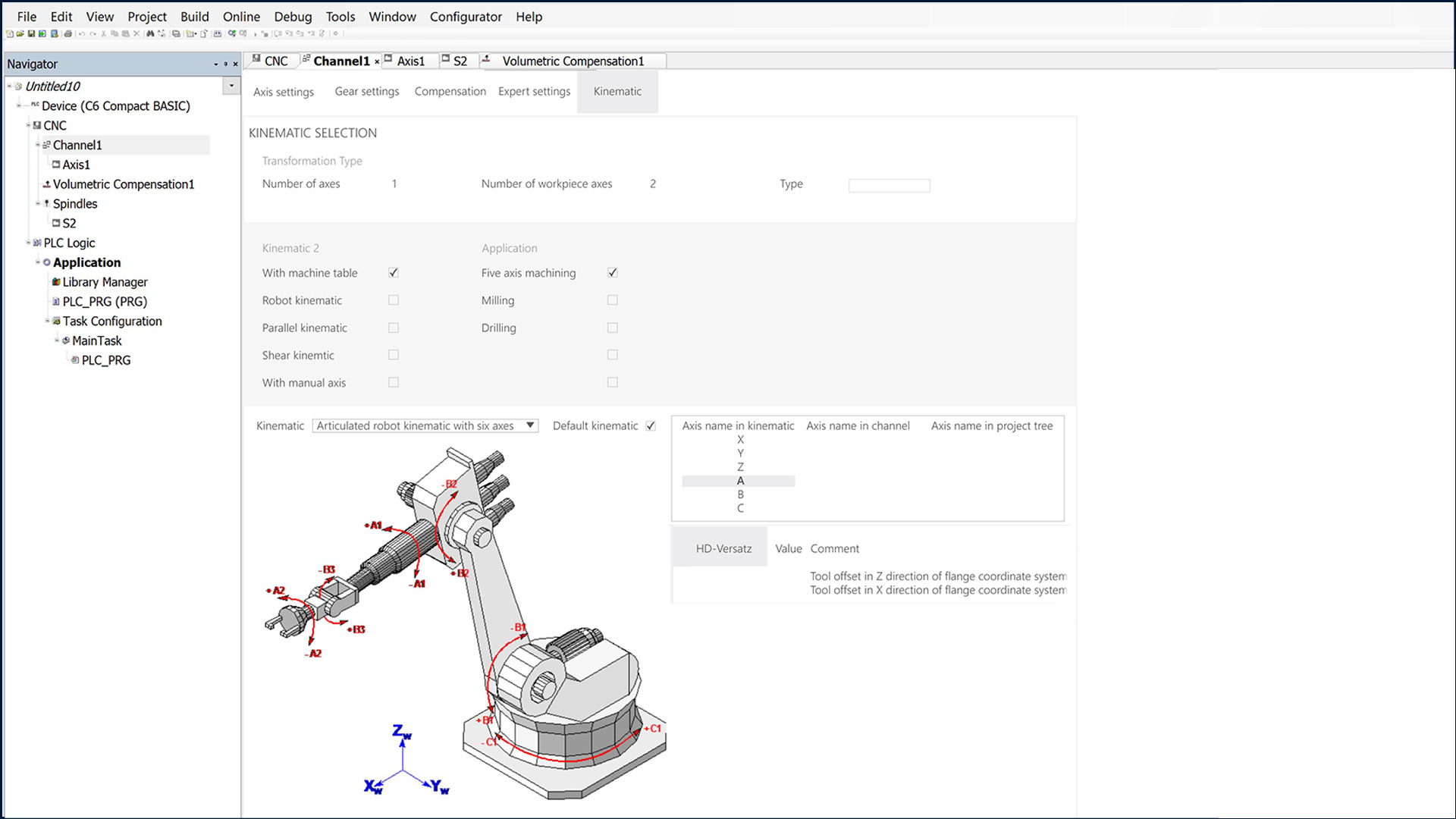

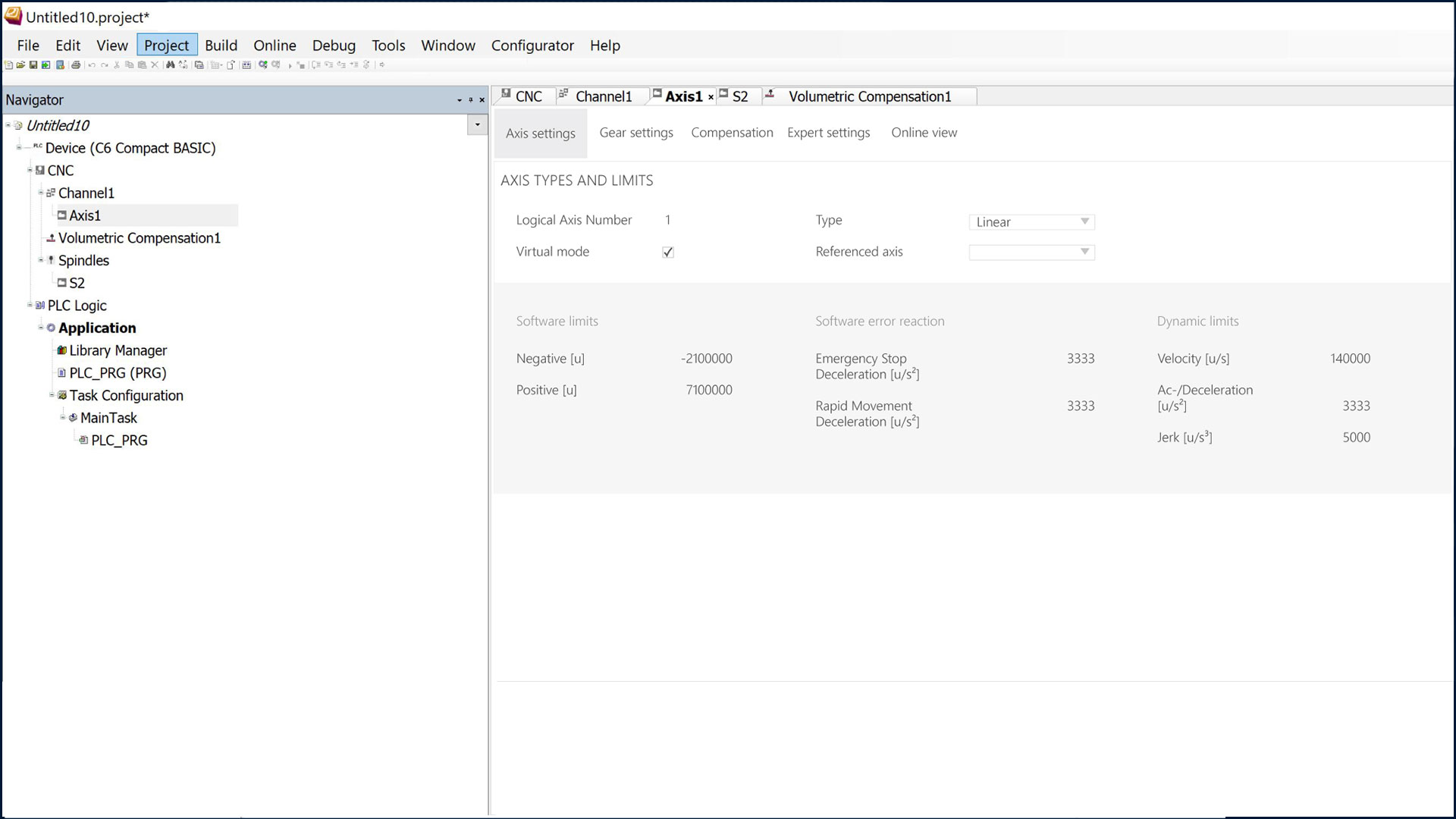

The CNC-Editor contains multiple forms to configure different CNC parameters. The usability of the editor was taken into account during development. Based on the selections made by the user, the CNC-Configurator generates complex data structure, which are handled by the runtime system to run motion control.

All configurations, done by the user are saved in the CODESYS project file.

Architecture:

Results:

The product was delivered to the customer on time. The final version contained additional input from beta customers (CNC machine builders). The CNC controller was officially released a few weeks after our final delivery.