Project

Machine condition monitoring

Development of a system that monitors the machine condition based on vibration.

Request/problem:

The customer needed a system to monitor the health of their machine. The existing system should be retrofitted with simple sensors to enable the machine status to be recorded as cost-effectively as possible. The solution must be flexible enough so it can be reused for new states and other machines/installations.

Solution:

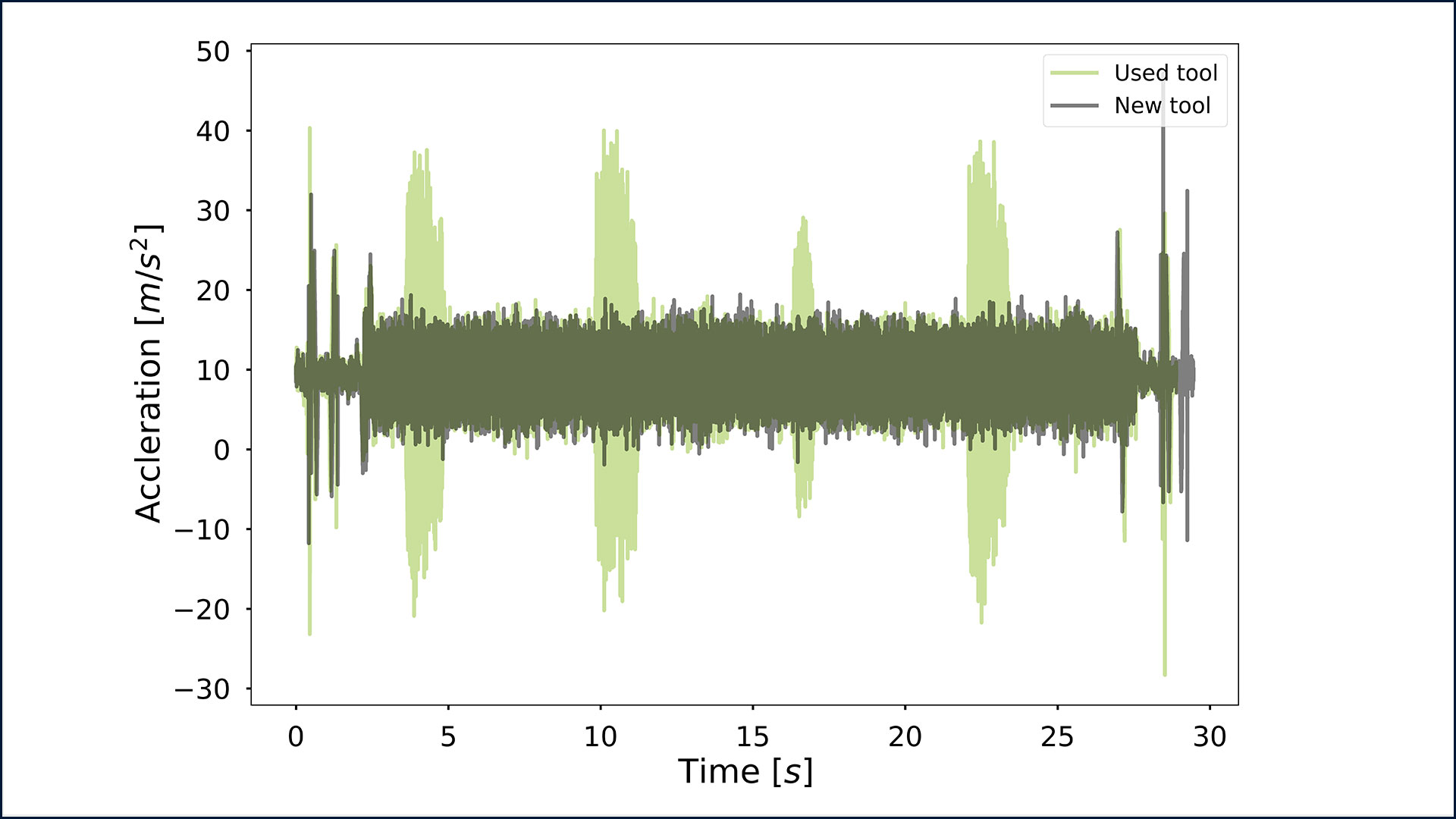

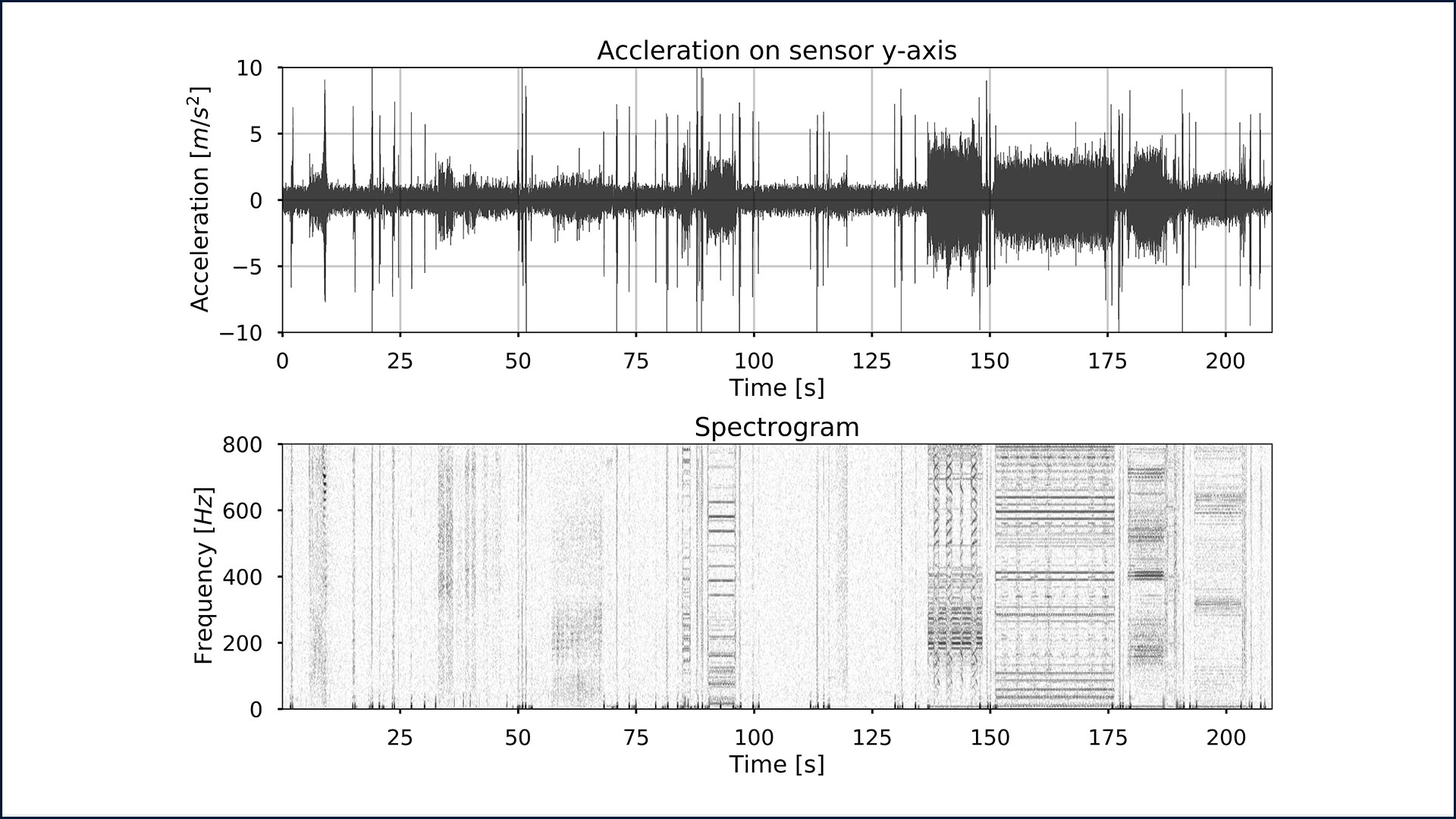

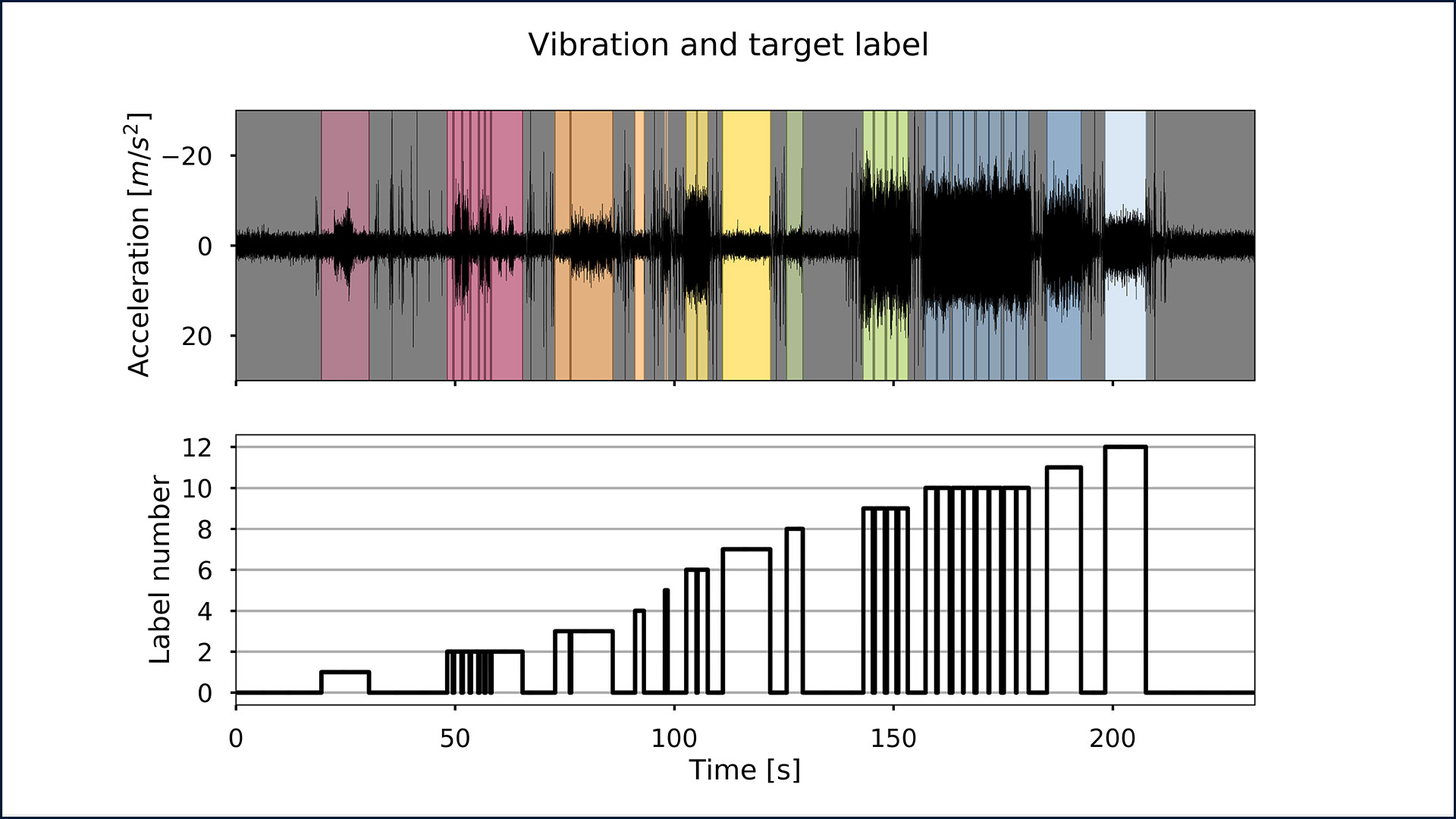

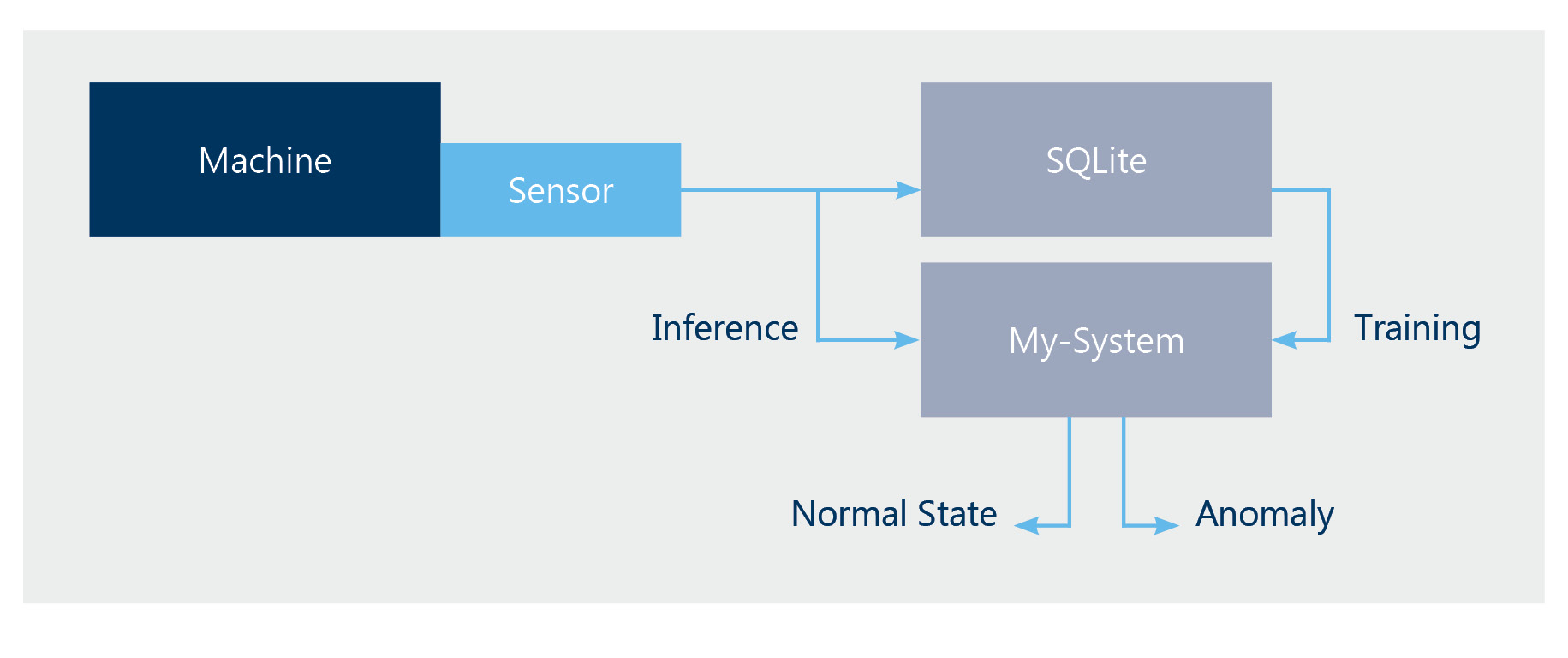

A cost-effective vibration sensor was retrofitted and data was collected over the course of several days during normal operation of the machine and stored in a database. With the help of unsupervised machine learning algorithms, the operating states were divided into characteristic areas. For this purpose, the sensor data are first transferred from the time domain to the frequency domain using Fourier transformation. Anomaly detection quantifies a deviation from known operating states and a warning is issued if a limit is exceeded.

Architecture:

Results:

After the training phase, the system was able to differentiate between several operating states based on the vibration. Since these states are created by unsupervised ML, this approach can also be implemented quickly for other machines of this type. The interpretation of the recognized states is carried out by the process expert. During operation, the anomalies detected are linked to the real error states over longer periods of time in order to create the basis for predictive maintenance.